Services

Industrial Solutions and Software (ISS) has African and Canadian roots, utilizing expertise in Canada and Africa to deliver solutions in Africa. Utilizing Canadian oil & gas. Mining, water and electrical power experience, as well as African mining, water and electrical power expertise, support will be strategically located in proximity to client assets in Africa. This allows us to provide cost-effective and responsive support and project configuration, design, and implementation services.

LOCAL PROJECT SUPPORT

We examine what organizations are doing to stay relevant and competitive in this fast-paced world, and which ones are doing it best. We then strategize using smart tools and global resources in order to understand the implications of every choice our clients can make. Get in touch to learn more about how this service can help you.

CLIENT FOCUSED

We are focused on developing a long-term relationship with our clients based on the delivery of high-value, cost-effective, and responsive project and support services. ISS seeks to understand your unique business drivers and provide solutions that will improve your competitive advantage.

STANDARD PROCESSES AND EXECUTION PLANS

ISS. provides our technical teams with project execution tools to guide ongoing project development and delivery. These tools include project administration, safety, document control, project and cost management, engineering, procurement, construction, and commissioning plans. Our best practice project tools help promote consistent project deliverables on each and every project.

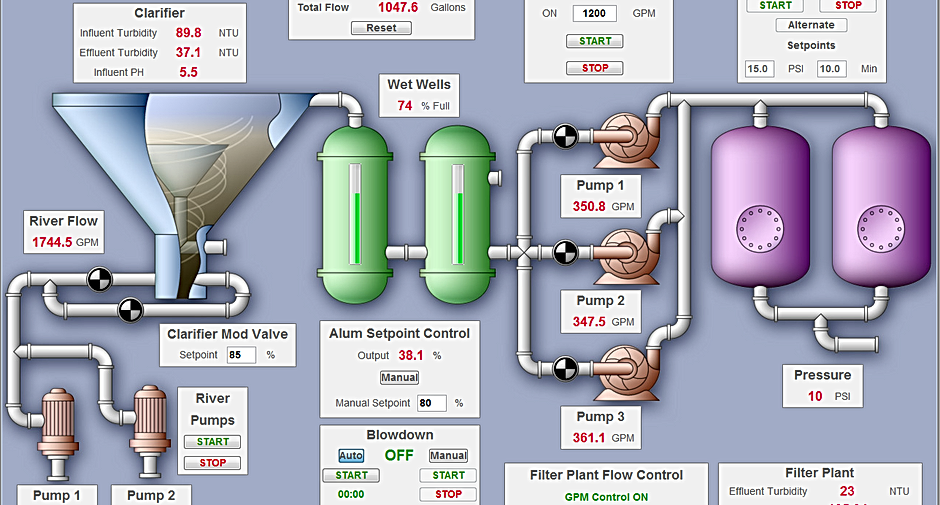

HMI SYSTEMS

HMI automation systems can connect to existing control systems, and provide key information to operators to operate, troubleshoot, and improve efficiencies.

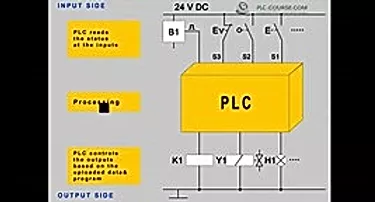

PLC SYSTEMS

From sequences, to ESD’s, logic control and decisions based on process inpurts or process control, PLC’s can be effective to automate processes

From sequences, to ESD’s, logic control and decisions based on process inpurts or process control, PLC’s can be effective to automate processes

DCS UPGRADES AND REPLACEMENTS

A distributed control system (DCS) is a computerised control system for a process or plant usually with a large number of control loops, in which autonomous controllers are distributed throughout the system, but there is central operator supervisory control. controllers located at a central control room or within a central computer. DCS concept increases reliability and reduces installation costs by localising control functions near the process plant, with remote monitoring and supervision.

Distributed control systems first emerged in large, high value, safety critical process industries, and were attractive because the DCS manufacturer would supply both the local control level and central supervisory equipment as an integrated package, thus reducing design integration risk. Today the functionality of SCADA and DCS systems are very similar, but DCS tends to be used on large continuous process plants where high reliability and security is important, and the control room is not geographically remote.

ith years of experience, our staff has the capabilities and expertise to take your business to the next level. At Industrial Automation Solutions, we combine our insights and skills to transform your processes and strategies, and in turn, your company. We’re proud to help shape and improve how our clients structure and manage their business.

TECHNICAL SUPPORT

Technical support and training is provided to ensure any issues can be resolved rapidly. Training provides self-sufficiency to maintain systems to peak performance.

PROJECT MANAGEMENT

On Time, On Budget

PROJECT MANAGEMENT

On Time, On Budget

PROJECT MANAGEMENT

On Time, On Budget